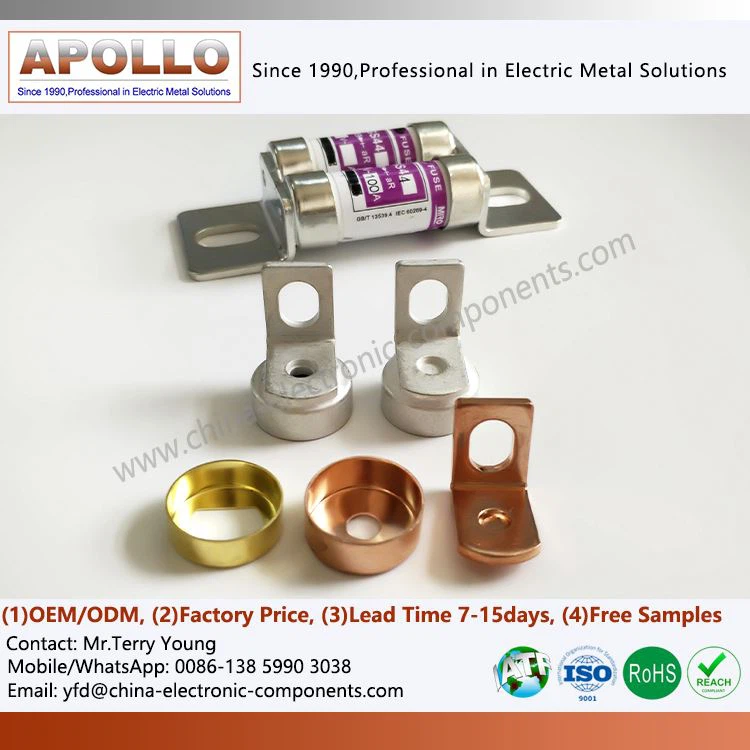

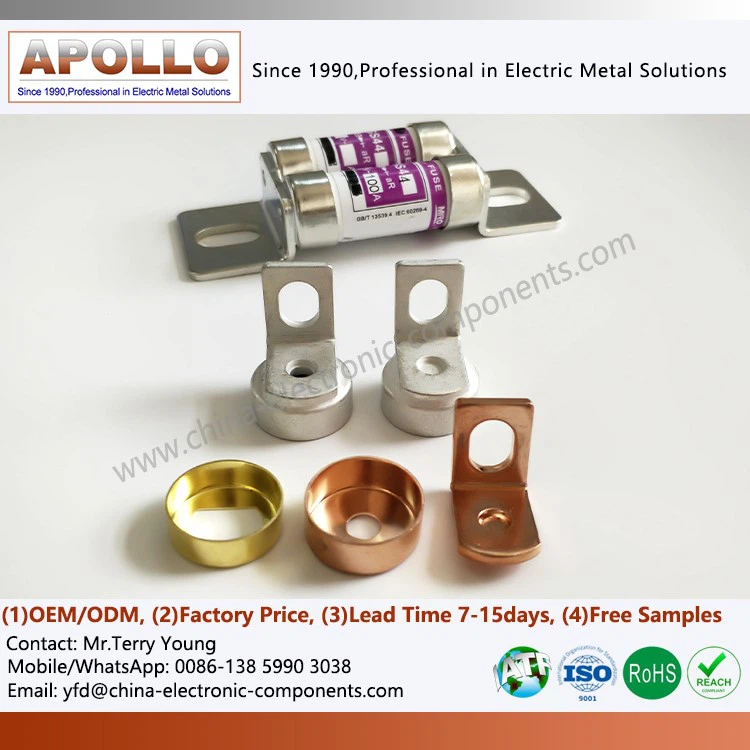

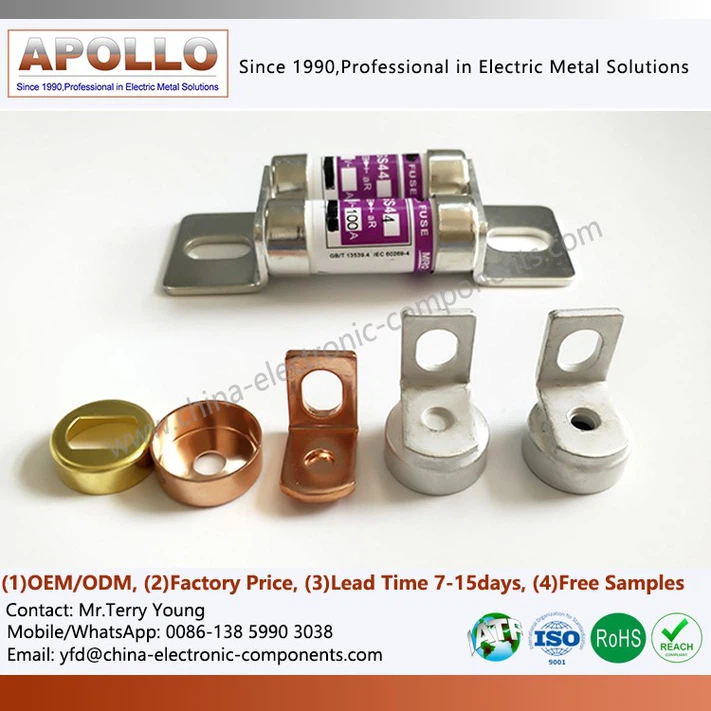

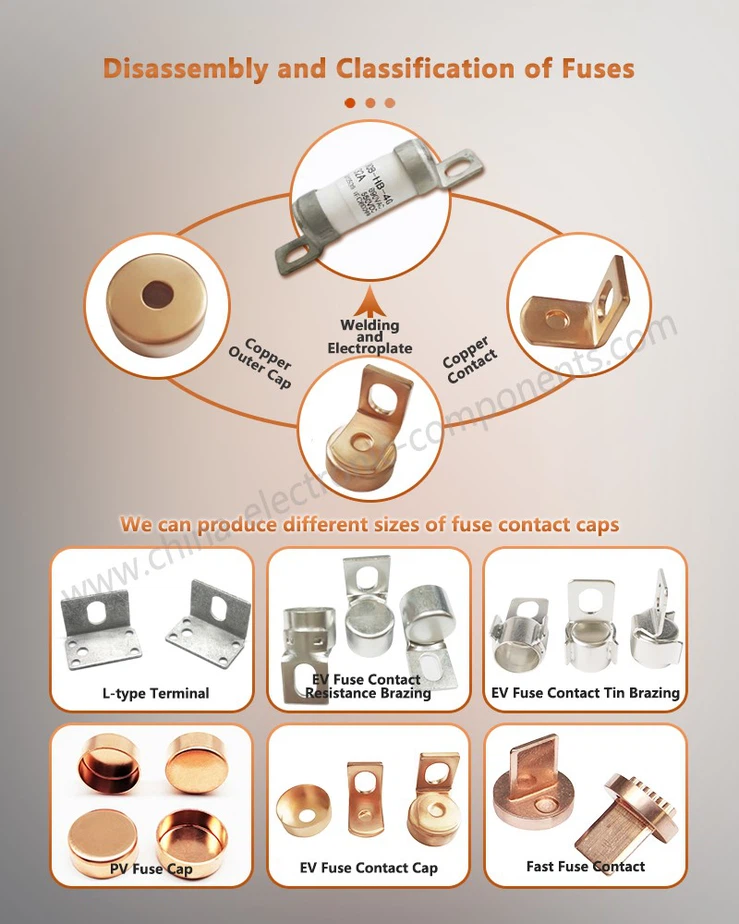

Copper Metal End Cap And Fuse Link Contact

Products Description

The Copper Metal End Cap and Fuse Link Contact is a critical component designed for high-performance electrical systems. Made from high-purity copper, it provides excellent electrical conductivity and superior thermal stability, ensuring reliable current transmission even under high load and elevated temperature conditions. The Copper Cap Contact for High Voltage Low Current EV Fuse are precision-machined to guarantee minimal contact resistance and secure mechanical fastening, effectively reducing overheating and energy loss. Widely used in industrial power systems, battery management equipment, and high-reliability electronic control modules, this product offers long-term durability, easy installation, and dependable performance, making it the preferred choice for professional buyers and engineering clients.

Electrical Performance and Safety

| Low Resistance, High Conductivity |

|

| High-Temperature Tolerance and Short-Circuit Protection |

|

| Corrosion Resistance and Aging Durability |

|

Easy Installation and Maintenance

Standardized Interface Design

Industrial-standard End Cap and Contact Welding Components design ensures compatibility with most fuse systems.

Precise dimensions facilitate quick installation and replacement.

Standardization simplifies field work and enhances engineering efficiency.

Multiple Installation Options

Supports soldering, bolt fastening, and other installation methods to suit diverse systems.

Simplified installation reduces error rates and labor time.

Optimized Design of Welded Joints design ensures long-term stability without additional support components.

Maintenance Convenience

EV Fuse Contact with Bolt Mount can be repeatedly disassembled and reinstalled for inspection or replacement.

Visual end cap design allows quick assessment of contact status.

Maintenance does not require replacing entire systems, reducing operational costs.

contact us

Hot Tags: copper metal end cap and fuse link contact, China copper metal end cap and fuse link contact manufacturers, suppliers, factory

You Might Also Like

Send Inquiry