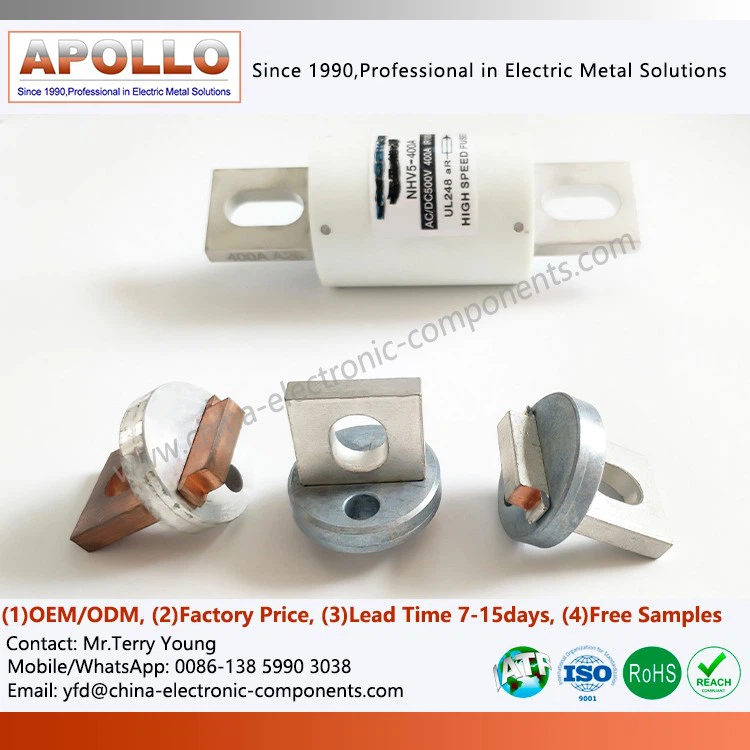

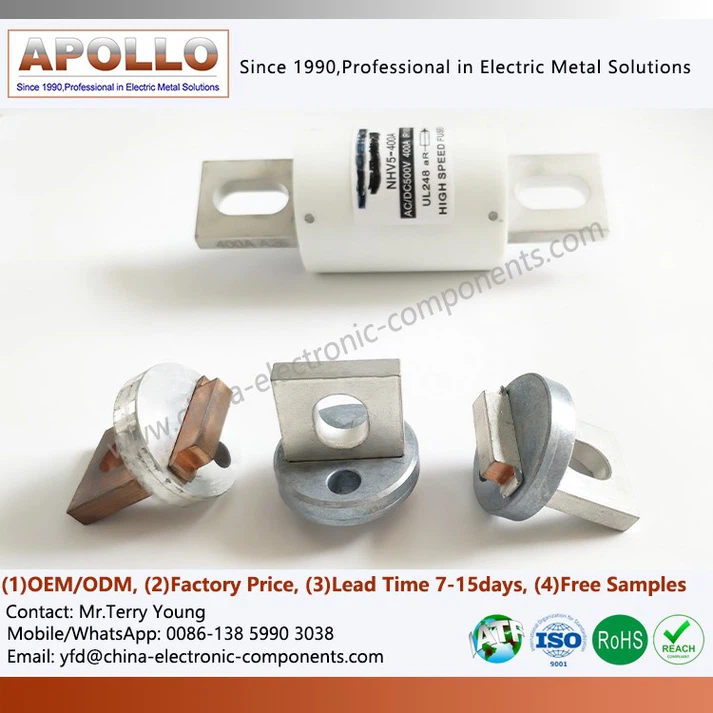

Copper Cap Contact For High Voltage Low Current EV Fuse

Products Description

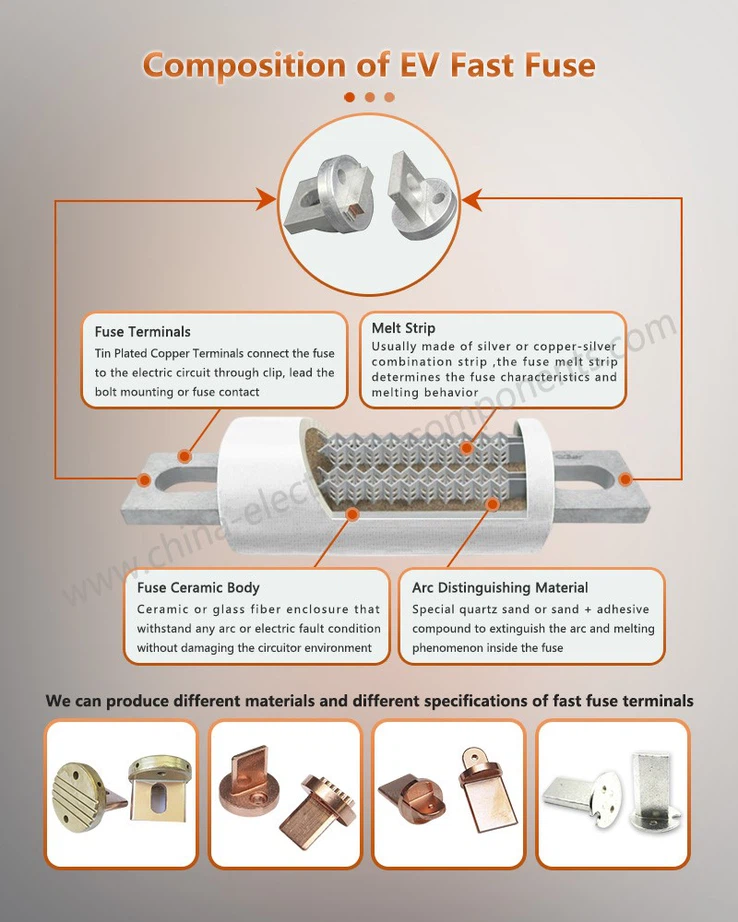

As a core conductive component specifically engineered for high-voltage low-current EV fuses, the Copper Cap Contact for High Voltage Low Current EV Fuse integrates premium performance and reliable safety to meet the rigorous demands of new energy vehicle electrical systems. Crafted with high-purity copper as the contact base and a flame-retardant insulation cap, this component ensures low-resistance power transmission while preventing leakage risks in high-voltage environments. It seamlessly adapts to scenarios such as EV battery packs, on-board chargers, and power distribution units, balancing easy assembly with long-term operational stability. Designed to reduce contact loss and enhance circuit efficiency, the Copper Cap Contact for Vehicle Fuse stands as a cost-effective and high-performance choice for EV fuse component procurement.

Core Material Selection Logic

High-Purity Copper Base for Conductivity

The contact part of the Copper Cap Contact for Electric Vehicle Fuse adopts high-purity electrolytic copper, which boasts excellent electrical and thermal conductivity. This material choice directly addresses the need for stable current transmission in low-current EV fuse systems, minimizing energy loss during operation. Its inherent durability also ensures resistance to wear under frequent use, aligning with the long service life requirements of EV components.

Flame-Retardant Insulation Cap Material

The iCopper Cap Contact for Eaton Bussmann Series EV Fuses is made of flame-retardant engineering plastic that meets strict high-temperature resistance and voltage breakdown standards. This material is specifically selected to withstand the harsh temperature fluctuations in EV engine compartments, preventing insulation failure and short circuits. It complies with automotive-grade safety norms, providing an additional layer of protection for high-voltage electrical systems.

Protective Plating for Longevity

The Copper Cap Contact for Semiconductor Fuses features a specialized plating process on the contact surface, combining enhanced conductivity with corrosion resistance. This plating effectively shields the copper base from oxidation and arc erosion, extending the component's lifespan even in high-frequency on-off cycles. The plating adhesion is optimized through rigorous process control, avoiding peeling issues during long-term use.

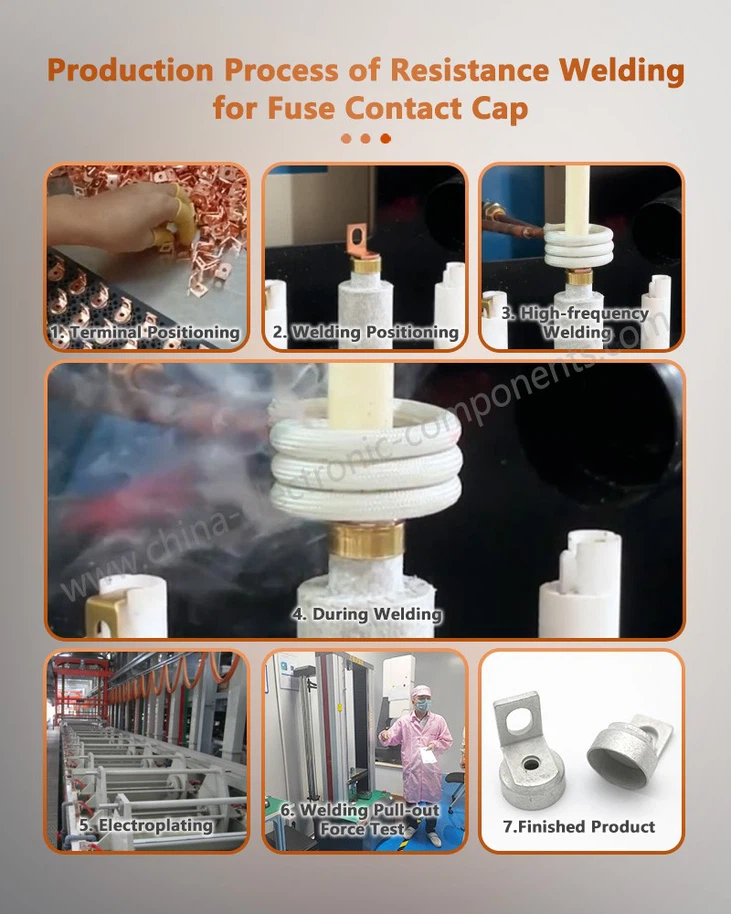

Process Design Advantages

| Integrated Injection Molding for Structural Stability | The assembly of the contact and insulation cap utilizes integrated injection molding technology, eliminating gaps between components. This design enhances the overall sealing performance and insulation reliability of the Cap and Contact for EV Charging Fuse, preventing dust or moisture intrusion that could affect electrical performance. It also simplifies the assembly process for EV fuse manufacturers, improving production efficiency. |

| Precision Stamping for Contact Consistency | The contact surface undergoes precision stamping to ensure uniform contact area across all units. Consistent contact dimensions reduce resistance variations between individual Cap and Contact for Fast Acting EV Fuse components, guaranteeing stable performance in batch applications. This precision manufacturing process meets the strict tolerance requirements of EV electrical systems. |

| Roll Plating with Post-Treatment for Uniformity | The plating process employs roll plating combined with professional post-treatment, ensuring even coverage of the contact surface. This technology ensures that every part of the Cap and Contact for Battery Pack Fuse receives consistent plating thickness, avoiding weak points in conductivity or corrosion resistance. The post-treatment process further enhances plating adhesion, maintaining performance integrity under extreme conditions. |

Quality & Compliance Assurance

Stringent Quality Control Processes

Raw materials for the Cap and Contact for Electric Vehicle (EV) Fuses undergo strict composition testing to ensure copper purity and plastic flame-retardant ratings meet standards. Three in-process inspections are conducted during production, covering dimensional accuracy, plating thickness, and insulation performance. Before shipment, each unit undergoes high-voltage breakdown and resistance testing to confirm electrical performance compliance.

Comprehensive Compliance Certifications

The Copper Cap Contact for Vehicle Fuse complies with the RoHS environmental directive, meeting the eco-friendly requirements of EV components. The insulation material holds UL94 flame-retardant certification, aligning with automotive electrical safety standards. The entire production process is governed by the ISO 9001 quality management system, ensuring standardized manufacturing and consistent product quality.

Reliability Testing for EV Environments

The component undergoes rigorous reliability testing, including temperature cycling, vibration resistance, and long-term aging tests, to validate performance in real-world EV operating conditions. These tests ensure the Copper Cap Contact for High Voltage Low Current EV Fuse maintains stability under extreme temperatures, humidity, and mechanical stress. Test reports are available upon client request, providing transparent proof of product reliability.

contact us

Hot Tags: copper cap contact for high voltage low current ev fuse, China copper cap contact for high voltage low current ev fuse manufacturers, suppliers, factory

You Might Also Like

Send Inquiry